What is MEP Engineering?

MEP engineering designs and coordinates the building systems that make a structure usable: Mechanical (HVAC) for comfort and air quality, Electrical for power and lighting (including low-voltage systems), Plumbing for water and drainage, and often Fire Protection for life safety. Good MEP design = comfortable occupants, lower energy bills, fewer construction surprises, and simpler maintenance. This guide breaks each system down in plain English, shows where MEP fits in the project lifecycle, explains BIM coordination and commissioning, and gives practical checklists for owners, students and engineers.

1. Simple analogy to start: think of a building like a living body

- HVAC (Mechanical) = lungs and temperature regulation (keeps air fresh and temperature stable).

- Electrical = nervous system (delivers energy/signals).

- Plumbing = blood and waste systems (delivers clean water, removes waste).

- Fire Protection = immune system / alarms (detects danger and responds).

This analogy helps: MEP systems keep the building alive, comfortable and safe.

2. Plain-English definitions

- MEP engineering: the practice of designing, documenting and coordinating Mechanical, Electrical and Plumbing systems so they fit the building, meet codes, run efficiently and are maintainable.

- MEPFP: the same as MEP but explicitly includes Fire Protection (sprinklers, alarms, smoke control).

- BIM coordination: using 3D models to spot and fix clashes between systems before construction.

3. The four systems — explained step-by-step, with everyday examples

Mechanical (HVAC) — what it is and why it matters

What it does: heats, cools, ventilates and filters air.

Everyday example: the AC in your office or the heater at home.

Components explained simply:

- Chiller/boiler: big machines that cool or heat water. Think of them as a building’s refrigerator/boiler.

- AHU (Air Handling Unit): pushes and filters air into rooms — like a fan + filter box.

- Ducts: metal “tubes” that carry air to rooms (like large air pipes).

- VAV (Variable Air Volume) box: a local controller to adjust airflow for a room.

Why owners care: comfort, occupant health (IAQ), and energy bills. Poor HVAC = sick building, high costs.

Electrical — the power and the brains

What it does: brings electricity to lights, plugs, servers, elevators and safety systems.

Everyday example: charging your laptop, lights turning on, backup power during outages.

Key pieces:

- Main switchgear & distribution panels: the building’s electrical “switchboard”.

- Transformers: change voltage levels, like stepping down high-voltage to usable power.

- Emergency/backup (generators, UPS): keep critical systems (IT, elevators, life-safety systems) running during outages.

- Low-voltage systems: fire alarms, CCTV, access control, data/IT cabling.

Why owners care: reliability, occupant safety, meeting tenant tech needs.

Plumbing — water in, water out, and drainage

What it does: supplies potable water, manages hot water, removes wastewater, and handles stormwater.

Everyday example: sinks, showers, toilets, roof drains.

Key parts:

- Hot and cold risers/pipes: vertical pipes running through the building.

- Pumps and tanks: move water when gravity won’t.

- Sanitary stacks & traps: carry waste safely to sewer lines and prevent odors.

Why owners care: health, water efficiency, and maintenance.

Fire Protection — life safety systems

What it does: detect fires and suppress them, plus manage smoke movement.

Everyday example: sprinkler heads, smoke detectors and fire alarm panels.

Key parts:

- Automatic sprinklers & piping

- Fire pumps (if needed)

- Smoke control systems

Why owners care: required by code, protects lives and assets, affects insurance.

4. Where MEP fits through the project lifecycle — practical breakdown

MEP work isn’t a single “design” step — it spans everything from early decisions to daily operations.

- Concept / Feasibility

- Decide system types (e.g., central plant vs rooftop units). Estimate energy use and space needs (e.g., mechanical rooms).

- Owner question: “How much rooftop space or basement will MEP need?”

- Schematic Design

- Rough equipment selection, major riser locations, initial load estimates.

- Design Development

- Full calculations (heating/cooling loads, electrical loads), preliminary duct and pipe routing.

- Construction Documents (CDs)

- Final drawings, specifications, schedules and tender-ready documents.

- BIM Coordination

- Combine models from architecture, structure and MEP; run clash detection and resolve conflicts in the model.

- Construction / Installation

- Shop drawings, prefabrication, on-site supervision, inspections.

- Commissioning

- Test, adjust and balance HVAC systems; verify alarms; handover documentation and staff training.

- Operations

- Routine maintenance, monitoring (BMS), retro-commissioning or upgrades for efficiency.

Owner tip: involve MEP early. Early decisions have the largest impact on cost and lifecycle performance.

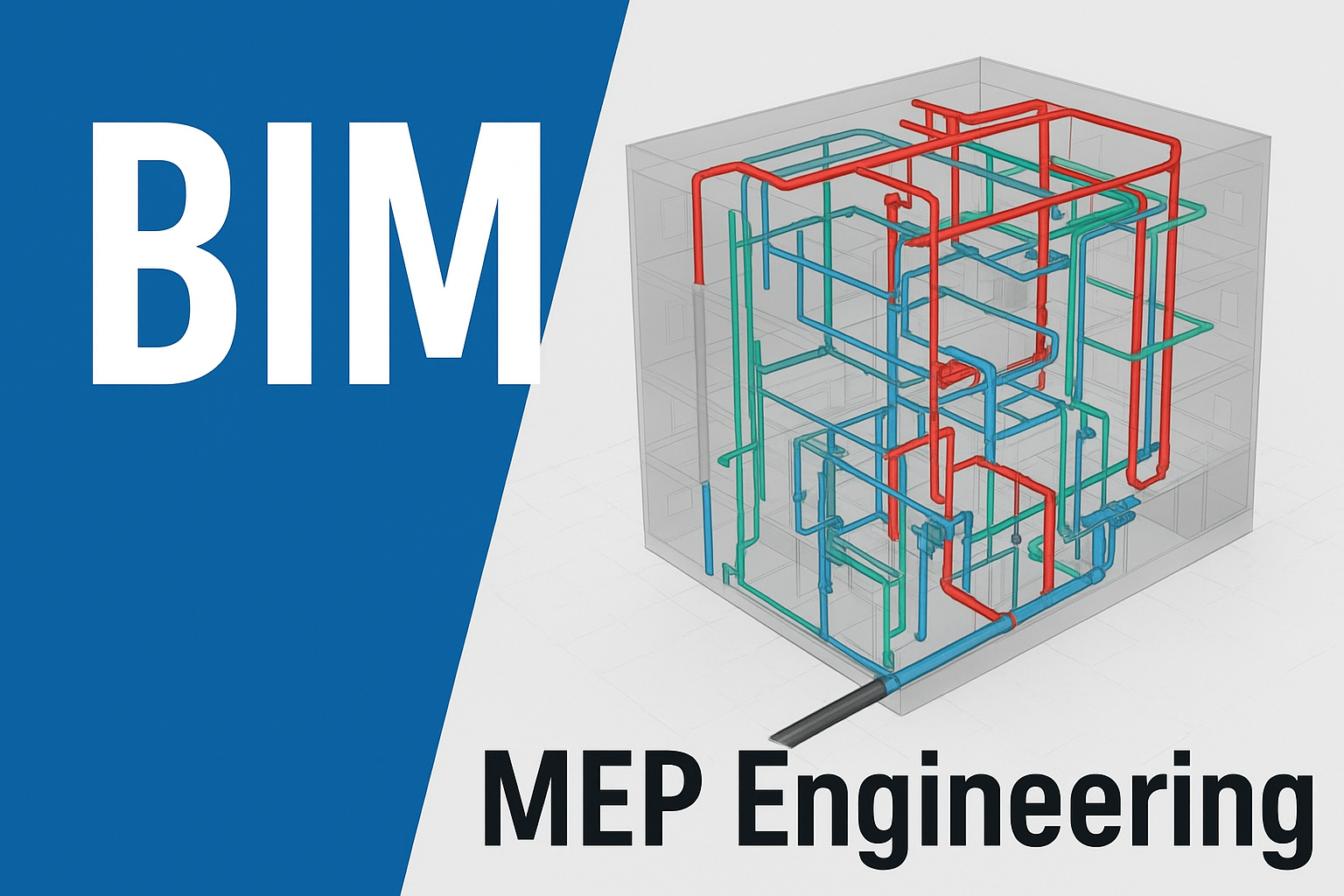

5. BIM & coordination

BIM (Building Information Modeling) isn’t just software — it’s a coordination process.

Simple workflow

- Each discipline (Architect, Structural, Mechanical, Electrical, Plumbing) builds its 3D model.

- Models are combined into a federated model.

- Use clash-detection tools (e.g., Navisworks) to find where ducts hit beams or pipes cross conduits.

- Resolve clashes in the models (not on-site).

- Produce coordinated shop drawings for fabrication.

Why it helps (in plain terms): you find and fix problems virtually—so workers don’t waste time and money fixing things on-site.

6. Commissioning — what it is, step-by-step

Commissioning = the structured process of testing systems so they work as designed.

Simple commissioning checklist

- Verify equipment installation matches drawings.

- Start-up and functional tests (does the AHU reach setpoints? do smoke dampers close?)

- Balance airflow and water flows.

- Test alarms and emergency power.

- Document results, fix issues, and retrain operations staff.

Why it matters: systems that are commissioned properly have fewer complaints and lower warranty/service costs.

7. Documents & deliverables you’ll actually see

- P&IDs / schematic diagrams: simple diagrams showing pipes, valves and equipment relationships.

- Duct & piping layouts: plans showing routes and sizes.

- Panel schedules & single-line diagrams (electrical): where power goes and how circuits are protected.

- Equipment schedules: lists of equipment with specs (e.g., AHU-01: 5,000 CFM).

- BIM models / clash reports and commissioning reports.

8. Simple owner-focused KPIs & what they mean

- EUI (Energy Use Intensity): energy per square meter or square foot per year — lower is better.

- IAQ indicators: CO₂ levels and particulate counts — important for health.

- System uptime %: percent time systems are operational (critical for hospitals/data centers).

- Lifecycle cost per square foot: includes initial cost + 10–30 years of operation/maintenance.

9. Realistic mini case (illustrative example)

Example: An office building used coordinated BIM early. The model showed a duct running exactly where a steel beam needed to be. The team moved the duct 0.3 meters in the model and updated shop drawings. On-site, the crew installed the moved duct — no rework or delay. Result: avoided a week of on-site patching and saved the contractor labor and material costs.

This is the kind of small coordination work that prevents big schedule slips.

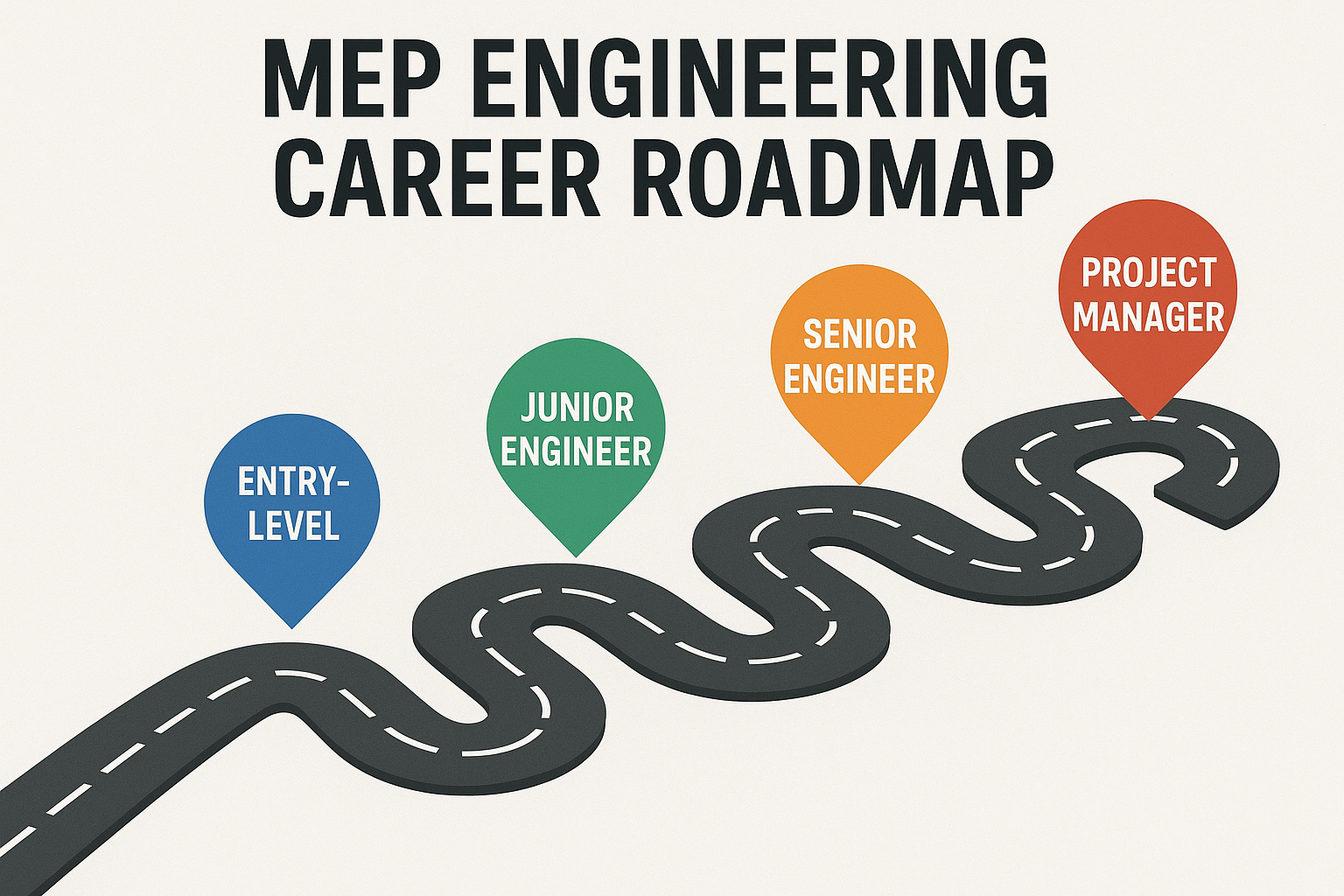

10. Career roadmap

Junior Level: learn basics — reading plans, simple load calcs, AutoCAD/Revit intro.

Senior Level: HVAC/electrical sizing, Revit MEP modeling, basic site visits.

Project Manager: lead projects, perform BIM coordination, run commissioning tests.

Tools to learn: Revit MEP, Navisworks, HAP/TRACE (HVAC loads), ETAP (electrical), Navisworks/Clash Detective.

Soft skills: clear communication, drawing reading, and problem-solving on site.

11. Glossary (quick reference)

- AHU — Air Handling Unit, pushes and filters air.

- Riser — vertical pipe or conduit that runs between floors.

- Single-line diagram — simple drawing showing main electrical distribution.

- BMS / BAS — Building Management System or Automation System (controls HVAC, lighting, etc.).

- Clash — conflict between two model elements (e.g., duct inside beam).

12. Practical checklists

Quick checklist for building owners before design starts

- Set energy and comfort targets (EUI, IAQ goals).

- Decide space for mechanical rooms, risers and plant.

- Choose delivery model (design-bid-build, design-build, integrated project delivery).

- Ask the MEP team about early BIM coordination and commissioning scope.

Pre-handover checklist for commissioning

- All equipment installed? ✔

- Functional tests recorded? ✔

- Operations staff trained? ✔

- O&M manuals uploaded? ✔

Conclusion

MEP is the practical heart of every building — the design and coordination of Mechanical, Electrical, Plumbing (and often Fire Protection) systems that make spaces comfortable, safe, and functional. Good MEP work touches every project stage: from early decisions about system types and equipment to BIM coordination, construction quality, commissioning, and long-term operations. When done right, it reduces construction risk, lowers operating costs, improves occupant health, and protects assets.

For owners, designers and students the takeaway is simple: involve MEP early, insist on coordinated BIM and rigorous commissioning, and measure success with real KPIs (EUI, IAQ, uptime and lifecycle cost). Those steps turn MEP from a hidden cost center into a predictable source of value — better comfort, lower bills and fewer headaches.

14. FAQs (short, plain answers)

Q. Is fire protection part of MEP?

A. Often yes — many projects use the term MEPFP (Mechanical, Electrical, Plumbing & Fire Protection). Even when fire protection is a separate specialist, it must be coordinated with MEP.

Q. Do small houses need MEP engineering?

A. Basic electrical and plumbing design are essential for safety and code compliance. Full MEP design is more common in multi-family or commercial buildings.

Q. What’s the difference between an MEP engineer and a contractor?

A. The MEP engineer designs and specifies systems; the contractor installs them on site. On many projects the engineer supports the contractor during construction.